Italian marble has always been a symbol of luxury, beauty, and timeless elegance. Whether it’s the grand floors of a five-star hotel or the smooth countertop in a modern home, the charm of Italian marble never fades. But have you ever wondered where it all begins? How does this stunning stone travel from deep inside the Italian mountains to the polished piece you see in your home?

In this article, let’s uncover the complete journey of Italian marble - from quarry to your home, step by step.

The Birthplace of Italian Marble: Nature’s Masterpiece

Italian marble is born deep within the Apuan Alps of Tuscany and other regions such as Carrara, Calacatta, Botticino, and Verona. These areas are world-famous for their marble deposits formed millions of years ago under immense heat and pressure, transforming limestone into marble.

Also Read

- Top South Indian Black Granites: From Galaxy to Absolute

- From Kishangarh to Ranchi – The New Destination for Premium Marble & Granite Buyers

- Quartz vs Full Body Slab: Which One Is Better for Your Kitchen Countertop?

- Italian Marble in Ranchi – Elegance Meets Local Needs

- The Story Behind Italian Marble Quarrying – From Mountains to Your Home

Each quarry region produces a distinct type:

Carrara Marble -

Pure white to blue-grey with soft veins, famous for sculptures and architecture.

Also Read Italian Marble is the Perfect Choice for Your Indian Home

Calcutta Marble -

Luxurious white background with bold golden or grey veins.

Also Read Difference Between Italian Marble and Regular Marble

Statuario Marble -

Pure white marble with dramatic grey veins, often used in high-end interiors.

These natural formations make each slab of Italian marble unique - no two pieces are ever the same.

Also Read How to Check the Quality of Italian Marble

THE 10 STEPS -

Step One: Identifying the Quarry Site

Before quarrying begins, geologists and engineers study the mountain area to determine the best quarry sites. They analyze:

Quality of the marble (color, texture, and vein pattern)

Geological structure (to avoid cracks or faults)

Environmental impact and safety

Only after detailed research and government approvals can a quarrying operation start.

Also Read How to Remove Stains from Italian Marble

Step Two: Extraction - Cutting the Mountain

This is where the real magic begins. Unlike old traditional blasting methods that caused cracks, modern quarrying in Italy uses advanced diamond wire saws and chain cutters. These machines allow precise cutting with minimal waste.

The Process:

1. Drilling Holes: Technicians drill a series of holes in a straight line to insert the diamond wire.

2. Cutting Blocks: The wire saw runs through the holes, slowly cutting large marble blocks from the mountain.

3. Splitting & Lifting: Once separated, hydraulic jacks or airbags lift and tilt the blocks onto the quarry floor.

Each block can weigh 20 to 50 tons, and safety during this stage is a top priority.

Also Read Marble vs Vitrified Which is the Best Flooring for Your Home

Step Three: Transportation to the Processing Plant

Once the raw blocks are extracted, they are carefully loaded onto heavy-duty trucks and transported to processing plants - mostly located near Carrara or Verona. These plants are equipped with advanced Italian machinery for cutting, polishing, and finishing.

For example:

- A block of Calacatta marble extracted from Carrara may travel to a plant in Verona for processing before being exported to India or the Middle East.

Also Read The Best Marble Shop : Tips for Quality And Variety

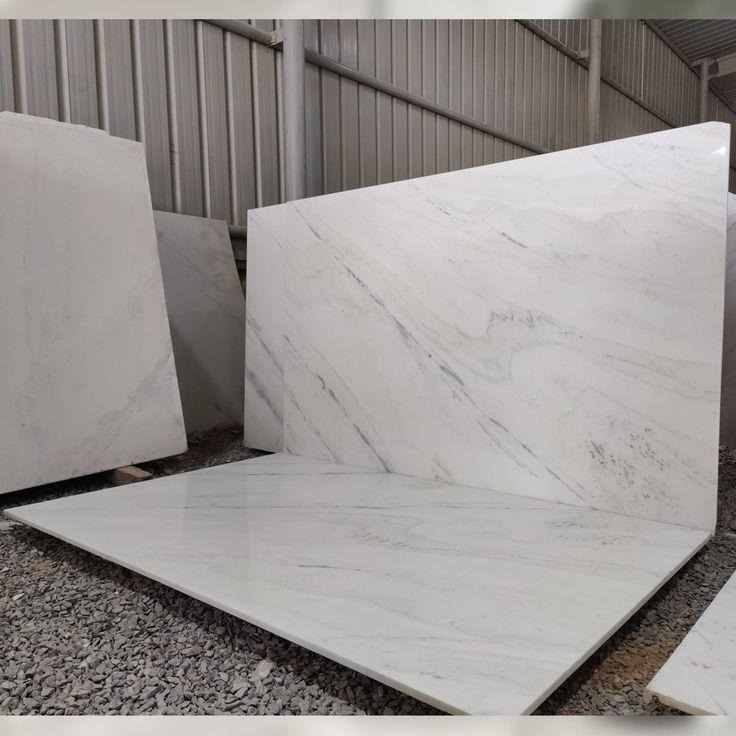

Step Four: Cutting into Slabs

At the processing plant, the massive marble blocks are converted into slabs using gang saws - machines fitted with dozens of blades that cut the stone simultaneously.

Gang Saw Cutting: Produces multiple slabs of uniform thickness (usually 16mm to 20mm).

Diamond Wire Saws: Used for special sizes and precision cuts.

The process is slow but ensures smooth, even slabs without cracks or damage.

Also Read Which Is Better for Bathrooms: Marble or Granite?

Step Five: Polishing for Perfection

Once cut, the slabs undergo multiple stages of polishing and finishing to bring out their natural beauty.

Common Finishes:

Polished Finish: High-gloss surface reflecting light - perfect for interiors.

Honed Finish: Matte, non-reflective finish - ideal for subtle, elegant spaces.

Leather Finish: Slightly textured surface - popular for countertops and modern designs.

Italian factories use automated polishing lines with diamond abrasives to achieve flawless surfaces. The final shine can reach up to 95% reflectivity, which is what makes Italian marble so stunning.

Also Read Types of Marble Flooring for Your Home

Step Six: Quality Inspection and Grading

Each slab is then inspected and graded based on:

Color consistency

Vein pattern

Thickness accuracy

Presence of natural fissures or spots

Grades like Premium, Commercial, and Standard are assigned accordingly. This ensures that customers receive slabs suitable for their project quality and budget.

Also Read Which Type of Marble Is the Best for Kitchens?

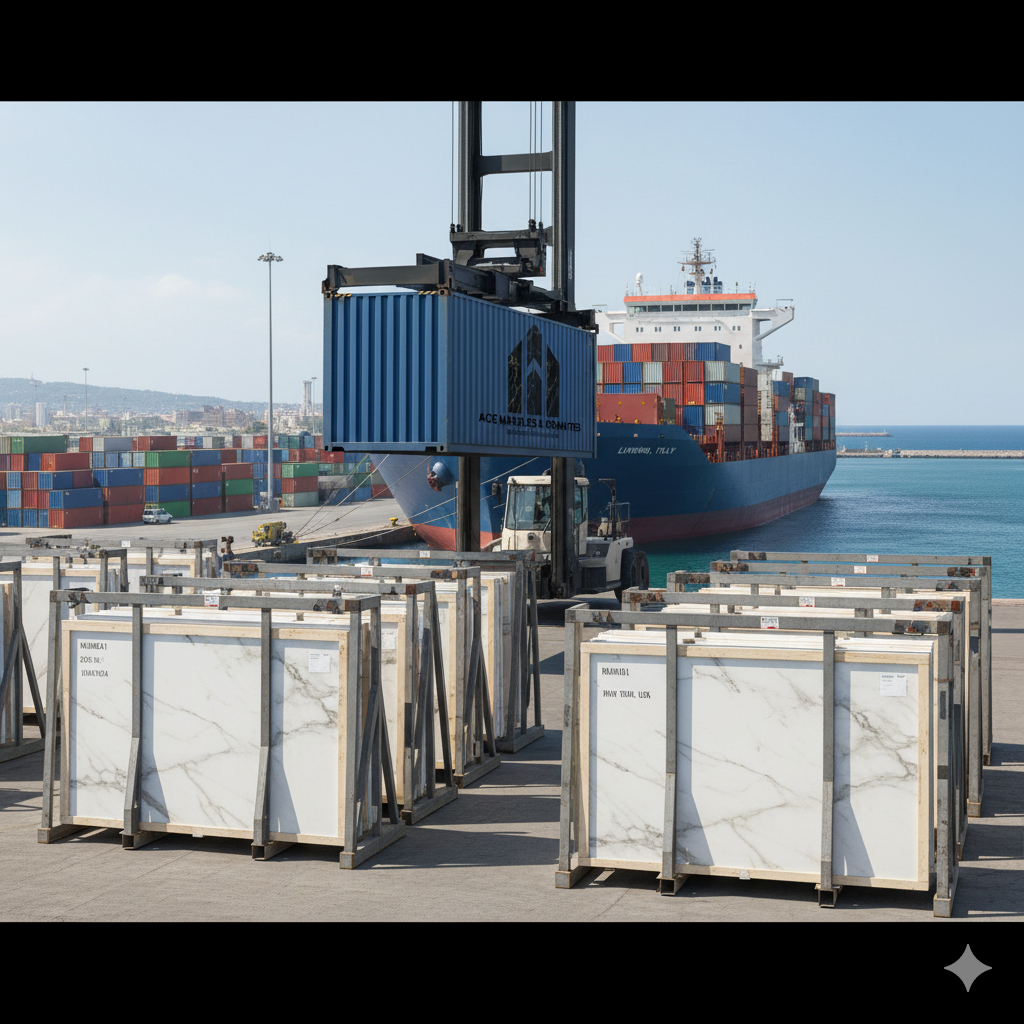

Step Seven: Global Shipping

After grading, the slabs are:

Packed in wooden crates or metal frames for protection.

Loaded into shipping containers.

Exported to various countries across the world, including India, UAE, USA, and others.

Italian marble is one of the most traded natural stones globally. The port city of Livorno is a major hub for exporting marble worldwide.

Also Read Brown-Black Granite

Step Eight: Arrival at Showrooms or Factories

Once the marble reaches its destination country, it is received by importers or distributors. For example:

> In India, companies like ACE Marble & Granite LLP (Ranchi) import premium Italian marble directly from Italy, store it in climate-controlled warehouses, and display it in exclusive showrooms for architects, interior designers, and homeowners.

This is where you, the customer, first see the marble in its polished form.

Step Nine: Custom Cutting and Installation

When you choose your marble slab, it’s then cut to size based on your design needs - flooring, countertops, wall cladding, or bathroom decor.

Installation involves:

Leveling the surface.

Laying the marble with adhesive or cement.

Grouting and sealing for protection.

Professional installation ensures the marble’s shine and durability last for decades.

Step Ten: From Mountain to Home - The Final Look

And finally, the journey completes - from the majestic mountains of Italy to the elegance of your home. Every slab you see carries millions of years of history, nature’s craftsmanship, and the artistry of Italian quarrymen and engineers.

When you walk on that polished Italian marble floor, remember - it’s not just stone, it’s a story of nature, passion, and perfection.

Conclusion

Italian marble is not just a construction material - it’s a legacy of nature and human craftsmanship. From careful quarrying to precise cutting, polishing, and installation, every step in its journey adds to its unmatched beauty and value.

So, the next time you admire that stunning white marble in your living room, you’ll know the extraordinary story behind it - the story that began high up in the Italian mountains.